Building a working wagon turntable

1:The wagon turntable comes in two parts, each ordered separately, so different types

can be used. The turntable can only move through 90 degrees, so only one track on

turntable is used, the other is dummy.

2:After cleaning up the grooves the rails fit in, cut 2 short lengths to fit on dummy track.

Take care, rail groove can be tight. I usually clean it out using some code 75 rail, then

use code 100 rail. I do it carefully, and have been spiked by rail on several occasions.

3:Cut and fit full length pieces of rail on the live track

4:Finish off by cutting short lengths to complete the dummy track. File grooves in the

live track to simulate the gaps in rail for dummy track.

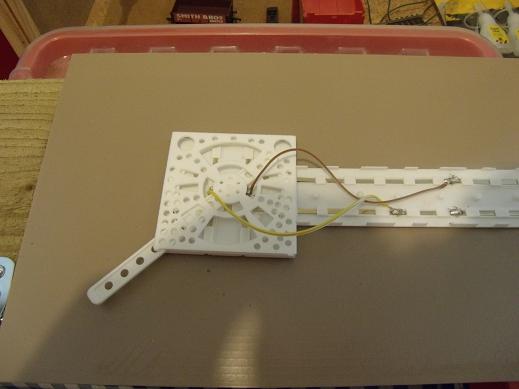

5:Turning over and the gaps in the plastic can be seen. Wires can be soldered in places

indicated, so it is possible to run locos onto or across turntable.

====================================

Now the turntable base.

6:Turn attention to the base, detach the operating arm , and insert through slot in side

of base, with the 3 fitting points for the turntable upwards. It might be necessary to

file the plastic a bit as gap is tight

7:The protrusion on other side of the arm fits into hole in middle of the base, Check to

see if free to rotate, and if necessary file down plastic on arm, carefully.

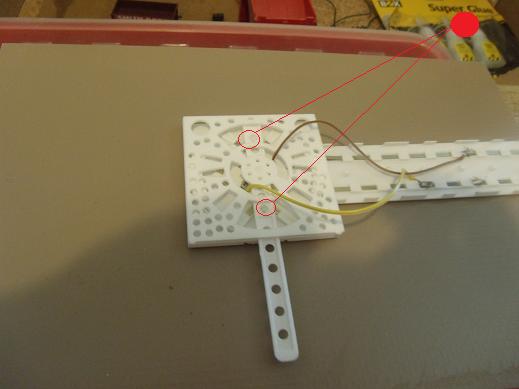

8:Fit turntable top, and check it rotates OK.

9:Turning the base over, it is possible to see the slots(marked) through which the wires

can be fed. Connect other end to the other connecting tracks as required. Make sure

wires are long enough and donít get tangled up. Leave extra space under base if necessary.

10:Connect up other inset track . Extending rails on these sections ,makes it easier to

connect to turntable base.

Check turntable with a suitable wagon. This is the slightly longer turntable, and

should make shunting easier.

The turntable base is deeper than the other track sections, so track sections need to

be raised by a few mm.

The turntable can be glued to operating arm(super glue) carefully. Best way I have

found is to move operating arm to half way, then put some superglue in the peg holes

plus a little bit of filler or solid glue, and clam both sides. Leave to set, remove clamps

and check for free movement.

To fix base down, pin or glue down at edges making sure turntable movement is not inhibited.

Now the fun starts .

Simon Dawson (Rue d'…tropal) 2015